Cylinder Service

Empty cylinder service is provided on cylinders in 2 liter capacities only.

Oxygen Cylinder

NB: Although we unable to supply oxygen with our cylinders, transporting cylinder gases by road falls within the Carriage of Dangerous Goods and Use of Transportable Pressure Equipment (amendment) Regulation 2005. It is important to be aware that licence'd companies must adhere to these regulations and usually charge an Extra Hazardous Goods delivery charge on shipping.

Because our cylinders are supplied empty, an extra Hazardous Goods Delivery charge is not added to your order. All cylinders are sold compliant to ISO13485 / MDDII. ISO13341 & BSEN 22434 and pass all safety requirements. We make sure all cylinders are currently in date before sale however cylinders must be tested every 5 years from the date of the cylinders last recorded test date.

We may be able appoint you a filling and re-filling service via a licensed company once you have purchased a cylinder.

Oxygen Cylinder

Oxygen cylinders are supplied in 2 liter capacities and are purchased in full by the customer with no contractual obligations. Each 2 liter cylinder holds 425 liters of compressed oxygen. Lifespan 3-6 months general usage. Each tank is sealed with manually open/close index valve.

Specification

BSEN / ISO13341 & BSEN / 22434

IS013485 / MDDII

Refill Service

We do not currently provide a refill service, however we may be able to advise reputable licensed companies that do supply this service.

Disclaimer: The oxygen source is not medical grade & not permitted for medicinal purposes.

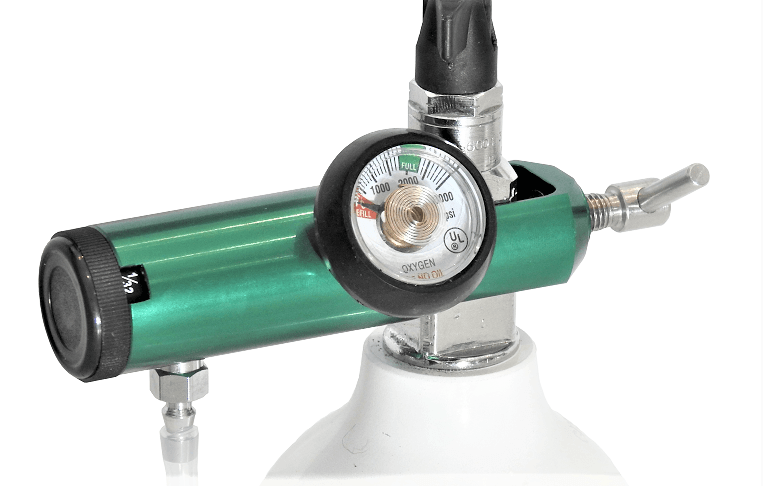

US Pediatric Regulators UL CERTIFIED

870 Pediatric regulators USA UL Certified, must correlate to the correct flow rate increments of your specific ozone generator. Non clinical generators are supplied with a visible chart for reference.

Clinical generators are not supplied with referencing charts and do not require manually selected flow rate increments as these types of generators have automatic regulating functions with set

pressures.

Flow Sequence LPM

1/32 - 1/16 - 1/8 - 1/4 - 1/2 - 3/4 - 1 LPM

UK Pediatric Regulators CE CERTIFIED

CE - marking: CE0434

Flow Sequence LPM:

0.1 - 0.2 - 0.3 - 0.4 - 0.5 - 0.6 - 0.7 - 0.8 - 0.9 - 1 LPM

Medical O2 different than the other O2 sources?

Ambient air consists of many gasses, but of that mix, only 19% of it is oxygen.

Ambient Air Circle Graph

Many applications will require a higher percentage than the 19%. That's where Concentrated Oxygen fills the need. Concentrated Oxygen refers to oxygen which is a minimum of 90% pure with moisture removed to a -100 deg F dew-point. It can be produced from an oxygen concentrator or delivered in a pressurized cylinder bottle.

There are a few methods used to produce the concentrated oxygen;

Pressure Swing Adsorption (PSA)

This system operates on a similar principle to the heat less desiccant dryer in that air is pressure fed to a molecular sieve. The selected media will be pressurized to then adsorb nitrogen, moisture, hydrocarbons, and CO2, leaving oxygen to flow through. When the pressure is reduced, the vapor, nitrogen, and other gases are dispersed and removed by the purged gas. The product gas contains about 90-95% O2 and a few percent each of nitrogen and argon. (Most small oxygen concentrators use the PSA method.)

Other methods of on-site oxygen generation include vacuum swing adsorption and cryogenic treatment which will not be addressed.

Concentrated Oxygen Graph

All concentrated oxygen is really the same and needs to be generated from oil-free compressors/liquefiers because any oil (of whatever nature) is highly flammable in 100% oxygen.

The difference between the four various oxygen grades, (Aviation, Medical, Welding and Research) is not in the quality of the oxygen but rather, the custody chain of the tanks.

Here's the issue: If a welding tank is used, but it's a rotated or swapped out tank, you will not know if the tank has been left open allowing contaminants to enter the tank. To then use that tank for medical applications would not be good, as impurities could be expelled from the tank.

A solution is: Buy a new oxygen tank, tag it in some manner, and when you get it filled/refilled, demand your personal tank back. You will then establish a chain of custody. The oxygen can be considered HIGH grade because you started with a clean tank having no contaminants. Because oxygen is considered to be a prescription drug, the FDA & MHRA is enforcing the chain of custody for the protection of the patients who need bottled oxygen. Companies that fill/refill Medical bottles need to be registered with the FDA or MHRA and will need to comply with regulations. Currently, the regulations require the company that fills the cylinders to either own the cylinders or to have written permission of the owners of the oxygen cylinders. Proper pre-fill inspections, labeling, and testing are also required.

https://www.ozonesolutions.com/info/is-medical-oxygen-different

About us

Registered United kingdom

Ozone Company UK.

Contact us

Email:Office@pharmi-tech.co.uk

Disclaimer:

Pharmi-tech makes no claims or suggestions regarding the use of ozone, oxygen, or ozone related products to treat or cure any illness, disease or any medical relation conditions.

© 2024

All Rights Reserved | Pharmi-tech UK